Kitchen Equipment

In early #kitchens the kitchen equipment consisted of an open fire for cooking, which was generally placed on the floor, the fuel being coal, wood, sundried cow dung cakes or balls lighted between two or three bricks on which the cooking vessel is placed. This is still practiced in rural India. #Kitchen #BNGHotelManagement #HotelManagement

Heavy and Light #KitchenEquipment

The need for a piece of kitchen equipment which could be moved in and out of the house led to the development of the galvanized iron bucket with a grill on the top followed by the smokeless “chullah”, the “tandoor” or traditional Indian oven which was followed by the gas and electric stove and finally the cooking range and the solar cooker. This is but an example of one type of kitchen equipment, but the last few decades have seen a complete revolution in the kitchen equipment industry, which now provides for the modern caterer a range varying from very simple easy-to-use gadgets to extremely complicated automatic devices. This development has been in response to the needs of the different types and sizes of catering units varying from the simple fresh fruit kiosk to the streamlined restaurant, which have sprung up to satisfy the ever increasing demands of people for eating out. Kitchen equipment for food service establishments is basically not very different from that used for cooking and serving food at home except that, because of the volume of food cooked and served, and the greater degree of handling required, it is constructed for greater quantity, durability, speed, efficiency and economy.

Over the years, the activities of catering establishments have become more and more professional and the objectives have been constantly directed towards utilizing kitchen equipment for maximum efficiency, and at the same time maintaining a service that is clean and attractive to both worker and viewer.

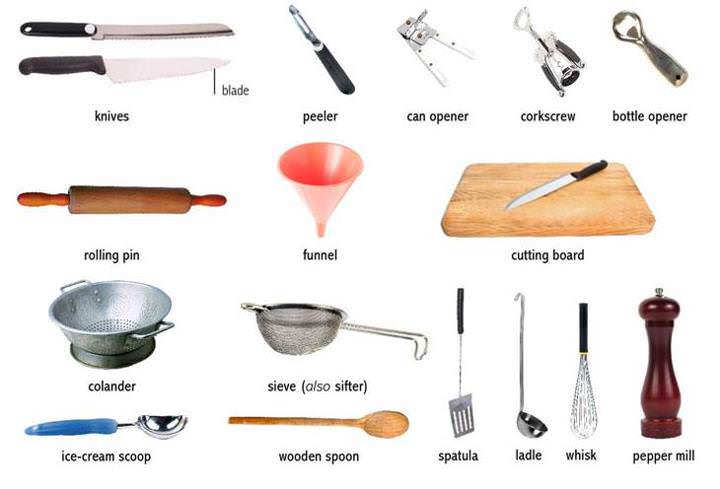

Thorough knowledge of kitchen equipment is essential for success in the kitchen. Few food service operations depend on nothing more than range and oven, an assortment of pots and pans, and knives and other hand tools. Modern technology continues to develop more and more specialized and technically advanced tools to reduce kitchen labour.

Much of this kitchen equipment is so complex or so sophisticated that only first-hand instruction and practice will teach you how to operate it effectively and safely. Other items, especially hand tools, is simple, and need no explanation, but require much practice to develop good manual skills.

There is a vast array of specialized kitchen equipment that is available for today’s kitchens. It would take a large book, not just a short chapter, to explain all of the many items you will come in contact with in your career – items such as pasta machines, crêpe machines, burger formers, breading machines, cookie droppers, beverage machines, Greek gyro broilers, doughnut glazers, conveyor fryers, and so on. In this technological age, nearly every year brings new types of tools to simplify various tasks.

INTRODUCTION TO QUANTITY kitchen EQUIPMENT

kitchen Equipment can be Dangerous. Modern cooking and food processing kitchen equipment has an extraordinary capacity to burn, cut, smash, mangle, and amputate various parts of the tender human body. It is not meant to intimidate you or scare you but to inspire a healthy respect for the importance of proper safety and operating procedures.

Not All Models Are Alike. Each manufacturer introduces slight variations on the basic kitchen equipment. While all convection ovens operate on the same basic principles, each model is slightly different, if only in the location of the switches. It is important to study the operating manual supplied with each item or to be “broken in” by someone who already knows that item well and has operate it.

Cleaning Is Part Of The Operating

Procedure:

Thorough, regular cleaning of all kitchen equipment is essential. Most large kitchen equipment can be partially disassembled for cleaning. Again, every model is slightly different. Operating manuals should give these procedures in detail. If a manual is not available, you must get the information from someone who knows the kitchen equipment.

Conserve Energy:

At one time it was standard procedure for the chef to turn on the ovens and ranges first thing in the day and keep them on all day. Today high-energy costs have made such practices very expensive. Fortunately, modern kitchen equipment has shorter preheating times. Know the preheating time for all your kitchen equipment, so you don’t need to turn it on before it’s necessary. Plan production so that high energy using kitchen equipment is not in use.

Your Hands Are Your Best Tools:

Machines are intended to be labour saving devices. However, the usefulness of specialized processing kitchen equipment often depends on the volume of food it handles. It takes less time for a cook to slice a few pounds of onions by hand than to set up a slicing attachment, pass the onions through it, and then break down and clean the kitchen equipment. This is why it is so important to develop good manual skills.

COOKING EQUIPMENT

Range Tops:

The range is still the most important piece of kitchen equipment in the kitchen, even though many of its functions have been taken by other tools, such as steamers, steam kettles, tilting skillets, and ovens.

Ovens:

The oven and the range top are the two workhorses of the traditional kitchen, which is why the two are so often found in the same units. Ovens are enclosed spaces in which food is heated usually by hot air or, in some newer kinds of ovens, by microwaves or infrared radiation.

In addition to roasting and baking, ovens can do many jobs normally done on the range top. Many foods can be simmered, stewed, braised, or poached in the oven, freeing the range top and the chef’s attention for other tasks.

There are many other kinds of ovens beyond those discussed here, but many of them are for specialty or high-volume uses. These include conveyor ovens, which carry foods through the oven on a steel conveyor belt; holding ovens or warmers, which are designed to hold many types of foods at serving temperatures for extended periods without drying out or overcooking (this category includes ovens that also cook the food, then automatically switch to holding temperature); and high-volume roll-in ovens, with large doors into which one can roll carts loaded with trays of food.

Conventional Ovens:

These ovens operate simply by heating air in an enclosed space. The most common ovens are part of the range unit, although separate oven units or ovens as part of a broiler unit are also available. Stack ovens are units that consist of individual shelves arranged one above the other. Pans are placed directly on the oven deck rather than on wire shelves. Temperatures are adjustable for each separate unit.

Convection Ovens:

These ovens contain fans that circulate the air and distribute the heat rapidly throughout the interior. Because the forced air, foods cook more quickly at lower temperatures. Also, shelves can be placed closer together than in conventional ovens, without blocking the heat flow.

Revolving Ovens:

These large ovens, also called reel ovens, are large chambers containing many shelves or trays on a ferris-wheel type attachment. This oven eliminates the problem of hot spots or uneven baking, because the mechanism rotates the foods throughout the oven. Revolving ovens are used in bakeshops and in high volume operations.

Slow-Cook-and-Hold ovens:

While the traditional oven is nothing more than a heated box equipped with a thermostat, some modern ovens have more sophisticated features, such as computerized, electronic controls and special probes that sense when a roast is done and tell the oven to switch from cooking temperature to holding temperature. Many of these ovens are designed to be especially useful for low-temperature roasting. The sensitive controls make it possible to cook at steady, reliable temperatures of 200oF (95oC) or lower and to hold foods at 140oF (60oC) for long periods. Large cuts of meat take many hours to roast at a low temperature like 200oF (95oC). By setting the controls in advance, the operator can even let meats roast overnight, unattended. These ovens are available as convection ovens and as regular, stationary-air ovens.

Combination Steamer Ovens:

A relatively new kind of oven is one that can be operated in three different modes: as a convection oven, as a convection steamer, and, with both functions on at once, as a high-humidity oven. Injecting moisture into an oven while roasting meats can help to reduce shrinkage and drying.

Barbecue Ovens or Smoke Ovens:

Barbecue ovens are like conventional ovens, but with one important difference: they are able to produce wood smoke, which surrounds the food and flavours it while it bakes or roasts. Special woods, such as hickory, mesquite, or various fruit woods such as apple or cherry, must be added to the smoke-producing part of the oven, according to the manufacturer’s instructions. This device is usually nothing more complicated than an electric heating element that heats small blocks or chips of the wood so that they are hot enough to smoke but not hot enough to burst into flame. Depending upon on the model, various cooking features are available. Thus, ovens may have smokeless roast/bake cycles, cold-smoke cycles (with the smoke element on but the oven off), holding cycles, and broiling capabilities.

Infrared or Reconstituting Ovens:

These units contain quartz plates that generate intense infrared heat. Infrared ovens are used primarily for reconstituting frozen foods. They bring large quantities of foods to serving temperature in a short time. The heat is even and controllable.

Microwave Ovens:

In these ovens, special tubes generate microwave radiation, which creates heat inside the food. Microwave cooking is discussed in detail as a separate chapter.

Broilers and Salamanders:

Broilers are sometimes called overhead broilers to avoid confusing them with grills. Overhead broilers generate heat from above; food items are placed on a grate beneath the heat source. Broiling is a favourite way of preparing steaks, chops, chicken, and many other items. Heavy-duty broilers produce very high heat and consume vast quantities of energy. Some broilers are said to go as high as 2000oF (1100oC) at the burner. Foods must be watched closely to avoid burning. Cooking temperature is adjusted by raising or lowering the grate that holds the food. Salamanders are small broilers used primarily for browning or glazing the tops of some items. They may also be used for broiling small quantities during off-peak hours. Salamanders are usually mounted above the range.

Grills:

Grills are used for the same cooking operations as broilers, except the heat source is below the grid that holds the food rather than above it. Many people favour the taste of grilled foods, because of the “charcoal” taste that is actually created by smoke from meat fats that drip into the heat source. Although smoke from meat creates the taste that people associate with grilled foods, actual wood smoke flavours, such as hickory or mesquite smoke flavour, and can be added to foods if those woods are burned in the grill under the food. In order to do this, you must use a grill designed to burn such fuels.

Griddles:

Griddles are flat, smooth, heated surfaces on which food is cooked directly. Pancakes, French toast, hamburgers and other meats, eggs, and many potato items are the foods most frequently cooked on a griddle. Griddles are available as separate units or as apart of a range top. Clean griddle surfaces after every use, so that they will cook at peak efficiency. Polish with a griddle stone or griddle cloth until the surface shines. Follow the grain of the metal to avoid scratching. Condition griddles after each cleaning or before each use, to create a no-stick surface and to prevent rusting. Procedure: spread a thin film of oil over the surface and heat to 400oF (200oC). Wipe clean and repeat until griddle has a smooth, no-stick finish.

Rotisseries:

Rotisserie broilers cook meats and other foods by turning them slowly in front of electric or gas-powered heating elements. Even though classical cooking theory categorizes spit cooking as roasting, these cookers are more closely related to broilers, because the foods are cooked by the infrared heat of the elements. Although they are especially suitable for chicken and other poultry, rotisseries can be used to cook any meat that can be fastened to a spit. Both enclosed (oven like) rotisseries and open or unclosed units are available. Small units hold about 8 chickens and size range all the way to very large models that can hold as many as 70 chickens. Because the heating elements are on the side (or sometimes above), the fats and juices don’t drip into the flames as they do with grills. Drip pans catch juices, which can be used for basting or gravy making.

Deep Fryers:

A deep fryer has only one use – to cook foods in hot fat. Yet because of the popularity of fried foods, this function is an important one. Automatic deep fryers are powered by either gas or electricity and have thermostatic controls that maintain fat at preset temperatures. Automatic fryers remove food from the fat automatically after a present time. Pressure fryers are covered fry-kettles that fry foods under pressure. Foods cook faster, even at a lower temperature.

Tilting Skillet:

The tilting skillet, also known as the tilting brazier and tilting fry pan, is a versatile and efficient piece of kitchen equipment. It can be used as a griddle, fry pan, brazier, stew pot, stock pot, steamer, and bain marie or steam table. The tilting skillet is a large, shallow, flat-bottomed pot. Or, to look at it another way, it is a griddle with 6-inch high sides and a cover. This skillet also has a tilting mechanism that enables liquids to be poured out of it. Power may be gas or electric. Clean the skillet immediately after each use, before food has time to dry on. Add water, turn on the skillet to heat it, and scrub thoroughly.

Steam-Jacketed Kettles:

Steam-jacketed kettles, or steam kettles, are sometimes thought of as stockpots that are heated not just on the sides as well. This comparison is only is only partly accurate, because steam kettles heat much more quickly and have more uniform and controllable heat than pots on the range.

Steam Cookers:

Steam cookers are ideal for cooking vegetables and many other foods rapidly and with minimum loss of nutrients and flavour. For this reason, they are becoming more common in both large and small kitchens.

PROCESSING kitchen EQUIPMENT

Mixers:

Vertical mixers are important and versatile tools for many kinds of food mixing and processing jobs, both in the bakeshop and in the kitchen.

Food Cutter:

The food cutter or food chopper, familiarly known as the “buffalo chopper,” is a common piece of kitchen equipment used for general chopping of foods. A variety of attachments make it a versatile tool.

Slicer:

The slicer is a valuable machine because it slices foods more evenly and uniformly than can be done by hand. Thus it is valuable for portion control and for reducing cutting loss.

Vertical Cutter/Mixer and Food Processor:

The vertical cutter/mixer (VCM) is like a large, powerful, high-speed blender. It is used to chop and mix large quantities of foods very rapidly. It can also be used for puréeing (soups, for example) and for mixing liquids.

HOLDING AND STORAGE kitchen EQUIPMENT:

Hot Food Holding kitchen Equipment

Several types of kitchen equipment are used to keep food hot for service. This kitchen equipment is designed to prevent the growth of bacteria that can cause disease. Because food continues to cook at these temperatures, it should be held for as short a time as possible.

- Steam tables are standard holding kitchen equipment for serving lines. Standard-size counter pans or hotel pans are used as inserts to hold the foods. Flat or domed covers may be used to cover the foods.

- A bain marie is a hot water bath. Containers of foods are set on a rack in a shallow container of water, which is heated by electricity, gas, or steam. The bain marie is used more in the production area, while the steam table is used in the service area.

- Overhead infrared lamps are used in service areas to keep plated food warm before it is picked up by the service staff. They are also used for keeping large roasts warm.

Cold Food Storage kitchen Equipment:

The quality of the food you serve depends to a great degree on refrigeration kitchen equipment. By keeping foods cold, usually below 40oF (5oC), the refrigerator (known in the trade as the ‘cooler’ or the ‘box’) guards against spoilage and bacterial growth. Freezers are used to hold foods for longer times, or to store foods purchased in frozen form. There are so many sizes, models, and designs of refrigeration equipment that it would be futile to try to describe them all.

To enable refrigerators and freezers to work at top efficiency, observe the following rules:

- Place items far enough apart and away from inside walls of refrigerator so that cold air can circulate. Freezers, on the other hand, work most efficiently when they are full.

- Keep the door closed as much as possible. When storing or removing an item, do it quickly and shut the door.

- Keep stored foods well wrapped or covered, to prevent drying and transfer of odours.

- Keep refrigerators spotlessly clean.

POTS, PANS, AND CONTAINERS:

Metals and Conductivity:

A good cooking utensil should distribute heat evenly and uniformly. If it does not, it will develop hot spots that are likely to burn or scorch the food being cooked. Two factors affect a pan’s ability to cook evenly:

Thickness of the metal. A heavy-gauge pot cooks more evenly than one made of thin metal. Thickness is most important on the bottom.

Kinds of metals. Different metals have different conductivity, which means the speed at which they transfer heat.

Pots and Pans and Their Uses:

- Stock pot. A large, deep, straight-sided pot for preparing stocks and simmering large quantities of liquids. Stockpots with spigots allow liquid to be drained off without disturbing the solid contents or lifting the pot.

- Sauce pot : Round pot of medium depth. Similar to stock pots, but shallower, making stirring or mixing easier. Used for soups, sauces, and other liquids. Sizes: 6 to 60 quarts (or liters)

- Round, broad, shallow, heavy-duty pot with straight sides. Used for browning, braising and stewing meats. Sizes: 11 to 30 quarts (or liters)

- Sauce pan. Similar to a small. Shallow, light sauce pot, but with one long handle instead of two loop handles. May have straight or slant sides. Used or general rangetop cooking. Sizes: 1 ½ to 15 quarts (or liters)

- Sauté pan, straight sided. Similar to a shallow, straight-sided saucepan, but heavier. Used for browning, sautéing, and frying. Also used for cooking sauces and other liquids when rapid reduction is required, because of broad surface area. Sizes 2 ½ to 5 inches (65-130mm) deep, 6 to 16 inches (160-400 mm) in diameter.

- Sauté pan, slope sided. Also called fry pan. Used for general sautéing and frying of meats, fish, vegetables, and eggs. Sloping sides allow the cook to flip and toss items without using a spatula, and they make it easier to get at the food when a spatula is used. Sizes: 6 to 14 inches (160-360mm) top diameter.

- Cast iron skillet. Very heavy, thick-bottomed fry pan. Used for pan frying when very steady, even heat is desired.

- Double boiler. Lower section, similar to a stockpot, holds boiling water. Upper section holds foods that must be cooked at low temperature and cannot be cooked over direct heat. Size of top section: 4 to 36 quarts (or liters)

- Sheet pan or bun pan. Shallow (1inch or 25 mm deep) rectangular pan for baking cakes, rolls, and cookies, and for baking or broiling certain meats and fish. Sizes: 18×36 inches (full pan), 18×13 inches (half pan) (46×66 cm and 46 x33 cm, respectively).

- Bake pan. Rectangular pan about 2 inches deep. Used for general baking. Comes in a variety of sizes.

- Roasting pan. Large rectangular pan about 2 inches deep. Used for general baking. Comes in a variety of sizes.

- Hotel pan also called counter pan, steam table pan, or service pan. Rectangular pans usually made of stainless steel. Designed to hold foods in service counters. Also used for baking and steaming, and foods can then be served from same pan. Also used for storage. Standard size: 12×20 inches. Fractions of this size (½, 1/3, etc) are also available. Standard depth: 2 ½ inches (65 mm). Deeper sizes are also available. (standard metric pan is 325 x 530 mm)

- Bain marie insert, usually called simple bain marie. Tall, cylindrical stainless steel containers. Used for storage and for holding foods in bain marie (water bath (. Sizes 1 to 36 quarts (or litres)

- Stainless steel bowl. Round bottom bowl. Used for mixing and whipping, for production of hollandaise, mayonnaise, whipped cream, egg white foams. Round construction enables whip to reach all areas. Comes in many sizes.

MEASURING DEVICES:

The following kitchen equipment is discussed in terms of U.S measurements. Comparable items in metric units also available.

- Scales: most recipe ingredients are measured by weight, so accurate scales are very important. Portion scales are used for measuring ingredients as well as for portioning products for service.

- Volume measures used for liquids have lips for easy pouring. Sizes are pints, quarts, half gallons, and gallons. Each size is marked off into fourths by ridges on the sides.

- Measuring cups are available in 1-, ½ -, 1/3-, and ¼ -cup sizes. They can be used for both liquid and dry measures.

- Measuring spoons are used for measuring very small volumes: 1 tablespoon, ½ teaspoon, and ¼ teaspoon. They are used most often for spices and seasonings.

- Ladles are used for measuring and portioning liquids. The size, in ounces, is stamped on the handle.

- Scoops come in standard sizes and have a lever for mechanical release. They are used for portioning soft solid foods. The number of the scoop indicates the number of level scoop-fuls per quart (or liter). In actual use a rounded scoop-ful is often more practical, so exact weights will vary.

- Thermometers measure temperatures. There are many kinds for many purposes.

- A meat thermometer indicates internal temperature of meats. It is inserted before cooking and left in the product during cooking.

- An instant read thermometer will give readings within a few seconds of being inserted in a food product. It reads from 0oF to 220o Many chefs carry these in their jacket pockets like a pen, ready whenever needed. Instant-read thermometers must not be left in meats during roasting, or thy will be damaged.

- Fat thermometers and candy thermometers test temperatures of frying fats and sugar syrups. They read up to 400oF

- Special thermometers are used to test the accuracy of oven, refrigerator, and freezer thermostats.

Utensils and Knives

KNIVES, HAND TOOLS, AND SMALL kitchen EQUIPMENT

Knife Materials

The metal that a knife blade is made of is an important consideration, since the metal must be able to take and hold a very fine edge.

- Carbon steel is the traditional favorite, because it can be honed to an extremely sharp edge. Its disadvantages are that it corrodes and discolors easily, specially when used with acid foods and onions. Also, it discolors some foods (such as hard- cooked eggs) and may leave a metallic taste.

- Stainless steel will not rust or corrode, but it is much harder to sharpen.

- High carbon stainless steel is a restively new alloy that combines the best aspects of carbon steel and stainless steel. It takes an edge almost as well as carbon steel, and it will not rust, corrode, or discolor. Knives made of this material are highly prized and are relatively expensive.

Knife Handles

The tang is the portion of the metal blade that is inside the handle. The best quality most durable knives have a full tang, which means that the tang runs the full length of the handle.

Knives and Their Uses

- French knives or chef’s knife – Most frequently used knife in the kitchen, for general purpose chopping, slicing, dicing and so on. Blade is wide at the heel and tapers to a point, blade length of 10 inches (260 mm) is most popular for general work. Larger knives are for heavy cutting and chopping. Smaller blades are for more delicate work.

This is your most important tool, so you must learn to handle it and care for it well.

- Utility or salad knife – Narrow, pointed knife 6 to 8 inches (160 – 200 mm) long. Used mostly for pantry work, cutting and preparing lettuce, fruits, and so on. Also useful for carving roast chicken and duck.

- Paring knife – Small pointed blade 2 to 4 inches (50-100 mm) long. Used for trimming and paring vegetables and fruits.

- Boning knife – Thin, pointed blade about 6 inches (160 mm) long. Used for boning raw meats and poultry. Stiff blades are used for heavier work. Flexible blades are used for lighter work and for filleting fish.

- Slicer – Long, slender, flexible blade up to 14 inches (360mm) long. Used for carving and slicing cooked meats.

- Serrated slicer- like a slicer, but with serrated edge. Used for cutting, breads, cakes, and similar items.

- Butcher knife- heavy, broad, slightly curved blade. Used for cutting, sectioning, and trimming raw meats in the butcher shop.

- Scimitar or steak knife- curved, pointed blade. Used for accurate cutting of steaks.

- Cleaver – Very heavy, board blade. Used for cutting through bones.

- Oyster knife – Short, rigid, broad bladed knife with a slight edge. Used for opening oysters.

- Clam knife – Short, rigid, broad bladed knife with a slight edge. Used for opening clams.

- Vegetable peeler – Short tool with a slotted, swiveling blade. Used for peeling vegetables and fruits.

- Steel – Not a knife, but an essential part of the knife kit. Used for truing and maintaining knife-edges.

- Cutting board – This is an important partner to the knife. Hard wood boards are favored by many chefs. Hard rubber or plastic boards are thought to be more sanitary, but there is some evidence that bacteria survive longer on plastic and rubber than wood. Cutting boards must be kept very clean.

Hand Tool and Small kitchen Equipment

- Ball cutter, melon ball scoop, or parisienne knife – Blade is a small, cup shaped half sphere. Used for cutting fruits and vegetables into small balls.

- Cook’s fork – heavy, two-pronged fork with a long handle. Some for lifting and turning meats and other items. Must be strong enough to hold heavy loads.

- Straight spatula or palette knife – A long flexible blade with a rounded end. Used mostly for spreading icing on cakes and for mixing and bowl scraping.

- Sandwich spreader – A short, stubby spatula. Used for spreading fillings and spreads on sandwiches.

- Offset spatula – broad blade, bent to keep hand off hot surfaces. Used for turning and lifting eggs, pancakes, and meats on griddles, grills, sheet pans, and so on. Also used as scraper to clean bench or griddle.

- Rubber spatula or scraper – Broad, flexible rubber or plastic tips on long handle. Used to scrape bowls and pans. Also used for folding in egg foams or whipped cream.

- Pie server – A wedge shaped offset spatula. Used for lifting pie wedges from pan.

- Bench scraper or dough knife – A broad, stiff piece of metal with a wooden handle on one edge. Used to cut pieces of dough and to scrape workbenches.

- Pastry wheels or wheel knife – A round, rotating blade on a handle. Used for cutting rolled –out dough and pastry and baked pizza.

- Spoons: solid, slotted, and perforated – Large stainless steel spoons, holding about 3 ounces. Used for stirring, mixing, and serving. Slotted and perforated spoons are used when liquid must be drained from solids.

- Skimmer – Perforated disc, slightly supped, on along handle. Used for skimming forth from liquids and for removing soled pieces from soups, stocks and other liquid.

- Tongs – spring type or scissors type tools used to pick up and handle foods.

- Wire whip – Loops of stainless steel wire fastened to a handle. There are two kinds of whips :

- Heavy whips are straight, stiff, and have relatively few wires. Used for general mixing, stirring, and beating, especially heavy liquids.

- Balloon whips or piano wire whips have mainly flexible wire. Used for whipping eggs, cream, and hollandaise, and for mixing thinner liquid.

- China cap – Cone shaped strainer. Used for straining stock, soups, sauces and other liquids.

Pointed shaped allows the cook to drain liquids thorough a relatively small opening.

Fine china cap or chinois (shee-nwah) China cap with very fine mesh. Used when great clarity or smoothness is required in a liquid.

- Strainer Round-bottomed, cup-shaped strainer made of screen-type mesh or of perforated metal. Used for straining pasta, vegetables, and so on.

- Sieve Screen-type mesh supported in a round metal frame. Used for sifting flour and other dry ingredients.

- Colander Large perforated bowl made of stainless steel or aluminum. Used to drain washed or cooked vegetables, salad greens, pasta, and other foods.

- Food mill A tool with a hand-turned blade that forces foods through a perforated disk. Interchangeable disks have different coarseness or fineness. Used for puréeing foods.

- Grater A four-sided metal box with different sized grids. Used for shredding and grating vegetables, cheese, citrus rinds, and other foods.

- Zester Small hand tool used for removing the colored part of citrus peels in thin strips.

- Channel knife Small hand tool used mostly in decorative work.

- Pastry bag and tubes Cone-shaped cloth or plastic bag with open end that can be fitted with metal tubes or tips of various shapes and sizes. Used for shaping and decorating with items such as cake icing, whipped cream, duchesse potatoes, and soft dough.

- Pastry brush Used to brush items with egg wash, glaze, etc.

- Can opener Heavy-duty food service type can openers are mounted on the edge of the workbench. They must be carefully cleaned and sanitized every day to prevent contamination of foods. Replace worn blades, which can leave metal shavings in food.

Care and maintenance

CARE AND MAINTENANCE OF kitchen EQUIPMENT

All kitchen equipment large or small, heavy or light, requires care in handling, use and storage on order to extend its life to the maximum, minimize depreciation and maintain it in a reasonably attractive and efficient condition while in use. In small catering establishment the care and maintenance is generally entrusted to those who operate the kitchen equipment as the types invested on are generally small or medium duty pieces. In larger establishments where heavy-duty kitchen equipment predominates, a maintenance department performs this function.

In the case of small pieces like cutlery, some metals need less care than others do. Stainless steel is the most non-corrosive and easy to-care for material, while plated cutlery tends to get scratched easily and with time requires replating.

With kitchen tools like the chef’s knives, choppers, etc. care is limited to preventing the blades from rusting in the case of iron blades, by keeping them dry and covered. It is also common practice to rub them with a little cooking oil to protect them from rusting through contact with air. With whisks and beaters it is the rotating parts or the wiry ends which need special attention. It is good practice to prevent food materials from on drying on the rotatory parts and posing a cleaning problem.

With heavier and larger pieces of kitchen equipment general cleanliness of the item and its environment is the guiding principle. The schedule below is a guide to the general care of most kitchen equipment.

SCHEDULE FOR CARE OF kitchen EQUIPMENT

- Keep all kitchen equipment clean.

- Wash all removable parts of kitchen equipment with suitable detergent and hot water after each use. In tropical summers this is not necessary, as the water in the taps is usually warm to hot, depending on the environmental temperature. After washing wipe kitchen equipment completely dry before replacing.

- All small kitchen equipment like cutlery, ladles, chopping boards, kitchen tools, etc. should be washed after use in (2) and replaced in drawers and racks built for the purpose and covered to prevent them from dust or dirt during storage.

- Check that all pieces are in working order. Close supervision at work is necessary to ensure a careful handling and to detect any deviations from effective operation, like an unusual sound, or fusing of warning lights, or ineffective thermostatic controls.

- Repairs must be attended to without delay to prevent the kitchen equipment from giving way and disrupting work for any period of time.

- A weekly, fortnightly or monthly programme for oiling or servicing the kitchen equipment to maintain movable parts or machinery in order is important. The service instructions provided by the manufacturer along with the kitchen equipment are a good guide to the service procedure that should be followed. It is useful to prepare an instruction card for every kitchen equipment carrying the manufacturer’s instruction in as simple a form as will be understood by the operators of the kitchen equipment. This card could be kept near each major piece of kitchen equipment.

- All electrical inputs to the kitchen equipment should be checked periodically to ensure that proper electrical load is available for efficient functioning.

- Insulations, plumbing, and other connections need periodic checks to keep kitchen equipment at optimum efficiency.

- Make full use of warranty periods to help train organization staff to learn regular maintenance procedures from the manufacture’s engineers.

- Assign the care of each machine to one responsible person.

Money, time and effort spent on care helps to maintain kitchen equipment in continuous working order, while that spent on repair can mean interruption in work causing unnecessary strain on staff, in addition to extra costs.

It is beneficial to keep records of all amounts spent on care and maintenance of every large kitchen equipment. This helps to estimate the depreciation every year. Excessive costs shown through records for a particular year can help to draw attention to high maintenance costs, which weighed against the cost of the kitchen equipment may result in a decision to change the model for a more efficient one. Records can also help to detect inefficient in operation, or defects in design or manufacture.

Thus, if kitchen equipment is cared for systematically and proper procedures followed, maintenance follows on its own to prolong the life and optimum usage of the kitchen equipment. The cleaning schedules for some commonly used kitchen equipment in small food service establishments are given under their respective heads:

Cooking Equipment: (Hot plates, gas stoves or ranges)

- Wipe the top daily while still warm, using wet cloth or sponge.

- Any foods spilled and burnt while cooking may require the use of mild detergent or scouring pad.

- For open burners, a weekly boil in warm soapy water will help remove any food particles that may have been the cause of blockade leading.

- Wipe dry with slightly oiled cloth.

Ovens

- Wash, rinse and outer surfaces daily, after every meal.

- Use liquid wax for enamel finished parts.

- Brush the inside to remove any sediments due to food particles charred during cooking. Any sticky areas may be wiped with a wet cloth after washing the oven and then switching it off.

- Clean all plastic knobs with cloth and wipe dry.

Refrigerators

- The outside surfaces should be cleaned as for oven daily.

- A weekly cleaning of the insides of a refrigerator is sufficient especially if the establishment is small. For this the machine should be disconnected, doors opened and the shelves removed and washed in warm water according to manufacturer’s instructions.

Preparation kitchen Equipment

- All parts, which are removable, should be cleaned after every use with light detergent.

- Sharp edges should be carefully handled for cleaning, drying and replacing immediately for use.

Coffee Urn

- Urns should be emptied after each meal and the insides cleaned with hard brush using a solution of sodium bicarbonate.

- Outer surfaces as for any other kitchen equipment.

Note: In general, it is good policy to follow manufacture’s instructions for care and maintenance of any kitchen equipment.

Maintenance Costs

The cost of maintaining any kitchen equipment should be determined on the basis of the following factors:

- Cost savings in terms of fuel consumption, as compared with the fuel bill prior to the installation of the piece.

- Cost of servicing and regular cleaning which would involve the cost of cleaning materials and detergents.

- Rate of depreciation calculated over the expected life of the kitchen equipment.

- Any savings that the installation would have resulted in, in terms of better utilization of raw materials and prevention of waste.

- Any savings brought about due to elimination of daily wage workers, as in the case of people being employed seasonally for peeling of vegetables for establishments which function for a limited period in the year, as for school meals, college canteens, and the like.