Spirits : Distillation – Pot Still and Patent Still

The origin of the art and science of distillation or Spirits are shrouded in the dim past. It is poetical to call its secret a gift of the gods, but it is more reasonable to suppose that it was discovered by some long-forgotten alchemist. The first Spirits distillers were probably perfume makers who made distillates from flowers, scents and water, and not from fermented liquids.

Apparently the science of Spirits distillation was known to the ancient Egyptians and Chaldeans. Long before the Christian era the Chinese obtained a spirit from rice beer; and Arak has been distilled from sugar cane and rice in the East Indies since 800B.C. Physicians such as Hippocrates of Cos (469-339 B.C.) and other Greek Medics used boiled-down wine and wine concentrates as part of the medical treatment to cure sores and heal wounds.

It is thought that the Arab physicians learned the art of distillation and Spirits from the Greeks. The Arabs advanced the technique further and fashioned words such as alcohol, alembic(still) and elixir. The first mention of distillation is attributed to an Arabian alchemist of the tenth century; later in the thirteenth century a Majorcan chemist and philosopher, Ramon Lull, described the process. Even before his time, the Celts of Eire and Scotia were producing a potable spirit which they called uisgebeatha or uisgebaugh – water of life.

In the Middle Ages, spirit was known as aqua vitae, water of life. In France it was referred as eau-de-vie. The twelfth century also saw the emergence of zhiznennia voda or water of life-later to be called vodka – in Russia and Poland.

In the fourteenth century, brandy was distilled in France and by the fifteenth century whisky-making was well established in the Scottish highlands. Rum was first made in the sixteenth century and about the same time Calvados was first distilled in Normandy, France. Gin came into existence as a medicine in Holland in the seventeenth century, while the eighteenth century saw the development of whiskey distilling in America. Cordials or liqueurs are flavoured beverages, whose flavour is obtained either by infusion or distillation of the flavouring compound, to which is then added simple syrup for sweetening. Miscellaneous spirits are obtained by distilling from various starchy or sugar-containing products.

DISTILLATION of Spirits

The principle of distillation is that ethyl alcohol vaporizes at a lower temperature than water –78ºC (172 º F) against 100ºC (212ºF). the distillation of alcoholic spirits depends on three factors:

- Ethyl alcohol vaporizes, becomes a gas, when temperature of 78 ºC (172 ºF) is reached. Water boils at 100 ºC. The still is an apparatus which allows the separation of water and alcohol to be carried out.

- Water is constantly vaporizing to some extend so every distillation will contain water.

- The minor constituents or congeners, which include higher alcohols, aldehydes, ethers, esters, volatile acids and organic compounds, give the product its distinctive, individual character of taste and aroma.

The first mention of distillation is attributed to Albukassen, an Arabic alchemist of the tenth century. With the development of modern science, methods have grown more efficient. There are two main types of still in general use today : the pot still and the patent still.

Find more detail information about Distilled beverages …here

THE POT STILL

The pot still originated in the Middle Ages and is based on the alchemist’s alembic. It is also known as the Albukassen Still. It is associated with separate, slow, low-temperature distillations. As a result, the end product contains a good proportion of congeners. Cognac, malt scotch, Irish whiskey, tequila, dark rums and some gins and liqueurs are pot still products. Pot stills are limited in the degree of proof they can achieve.

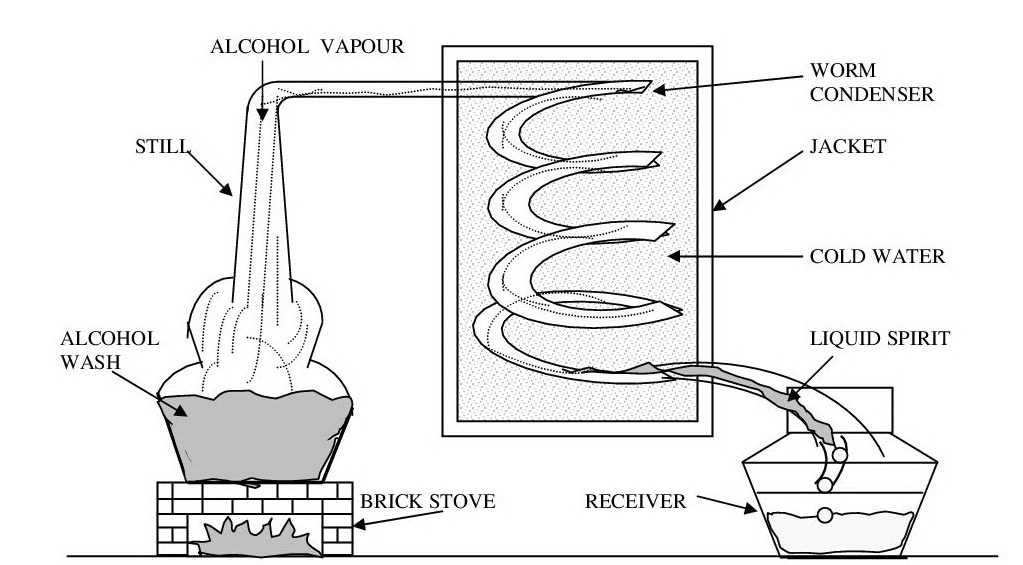

The Pot Still is shaped like a giant onion and consists of two parts: a Still and a Worm condenser. The still is made of copper, which is a good conductor of heat and also builds up a good resistance to the effects of acids which are normally capable of dissolving metal. The worm condenser is a spiral tube also made of copper and this is connected to the still by a copper pipe. The worm passes through a jacket or condenser, which speeds up the condensation of the alcohol-rich vapours. The pot still is time consuming and costly to operate. It needs to be cooled, cleaned and refilled after each distillation, but it produces spirits of remarkable individuality, quality and flavour.

The fermented liquid is placed in the still and slowly heated over a naked flame. When the temperature reaches 78 ºC, the alcoholic vapours rise and are led through a system of piping called the Worm to a cooling apparatus – the condenser – and condensed into a liquid containing about 30% alcohol. This is re-distilled. The first part of the distillate to emerge is known as the heads or foreshots and contains a high proportion of methanol, which can be toxic and very unpalatable. This is put to one side to be dealt with later. The central portion or the heart of the distillation – the best part – has an alcoholic strength of about 80% and is channelled into the spirit receiver and ultimately into maturing casks. The final part of the distillation, known as tails, feints or after-shots, is weak in alcohol and contains the fusel oils and other impurities. This is now added to the reserved heads and sent back to be re-distilled and refined. The new spirit may be reduced in strength to 63% by the addition of de-ionized water. The spirit now requires resting, maturing, blending, reducing in strength and perhaps colour enhancement before being bottled for sale.

THE PATENT STILL

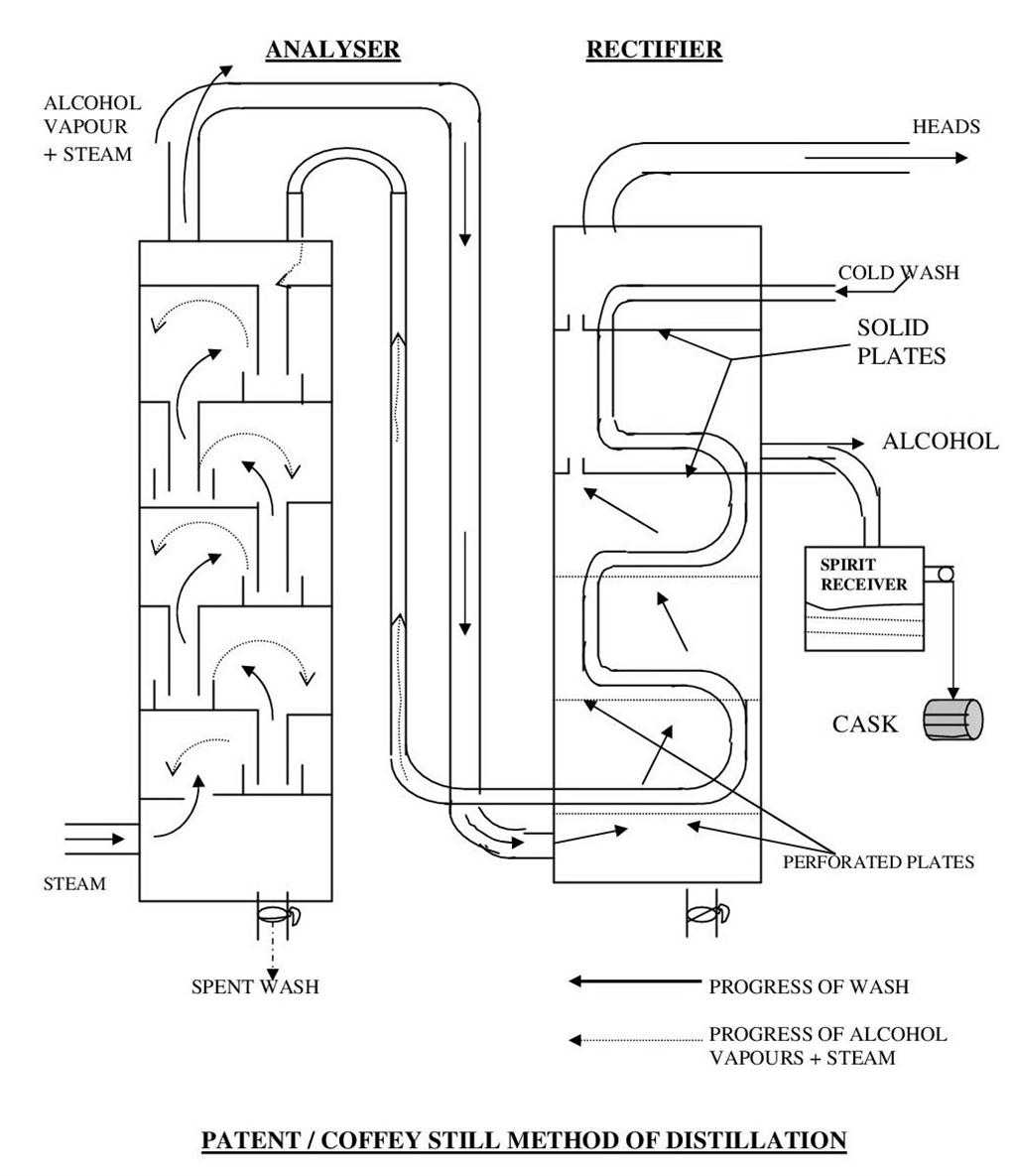

In 1826, Robert Stein of the famous Scotch whisky distilling family, invented the patent still. This was later perfected by Aenas Coffey, a Dublin excise officer who patented the still in 1831 which replaced Stein’s, and is now known as Coffey or Patent Still. It employs the principle of distillation by steam and uses rectification to make the end product as pure and congener-free as possible. It produces a continuous flow of high strength – about 90% -alcohol. It is cheaper than pot still to operate as it is lighter on fuel. Because its system of operation is continuous, it does not require the labour-intensive tasks of emptying, cleaning and refilling. The patent still is associated with all the light spirits such as vodka, gin, white and light rums and grain whiskies which are later used for blending.

The patent still consists of two columns each about 18m high. One column is called the analyser, whose role is to separate the constituent parts. The other column is the rectifier which raises the strength of and purifies the spirits , and condenses the alcoholic vapours. Each column is sub-divided horizontaly into chambers by perforated copper plates which have a drip pipe leading to the chamber underneath. Both columns are preheated by steam and the fermented liquid or wash enters at the top of the rectifier and gradually descends through it inside a pipe. By the time the wash reaches the bottom of the rectifier it is almost at boiling point. It is then pumped into the analyser where it gradually makes its way downwards through perforated plates and bubble caps. As it descends, it is met by a current of raw steam which has been injected under pressure boils the wash and produces alcoholic vapours. These rise and are channelled by a pipe into the bottom of the rectifier. The spent wash is removed at the bottom of the analyser.

Inside the rectifier, the alcoholic vapours pass through a series of perforated plates. As they rise they meet at certain points the cold wash being carried down the rectifier by the wash coil. Partial condensation takes place – the vapours getting cooler and the wash, on its way up in the analyser, getting hotter. When the spirits vapours reach two thirds of the way up in the rectifier, they hit a cold spiral plate or water frame and precipitate. The first liquid to emerge-the heads or foreshots-is removed and sent back to the analyser because it is pungent and needs further refining. The comparative pure spirits which follows is guided into a spirits receiver. This will be reduced in strength by deionised water and matured for a short time before being treated according to style.